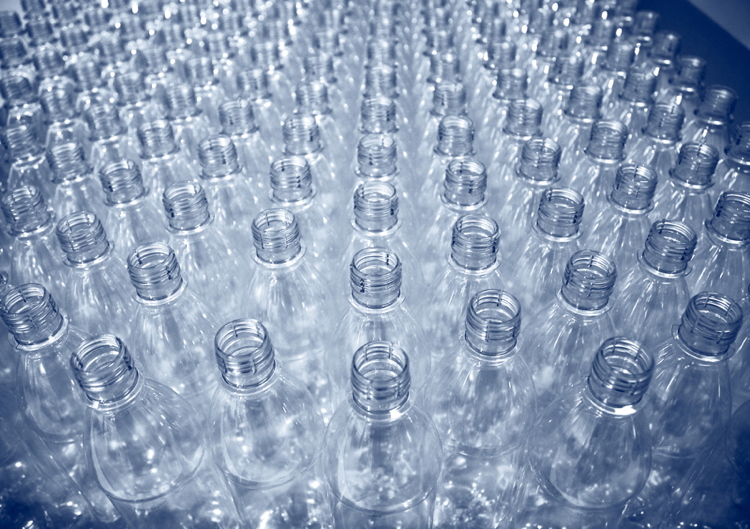

GOTHENBURG – Academics at Chalmers University of Technology in Sweden have developed a method of using the carbon atoms from mixed plastic waste in the manufacture of virgin-grade raw materials.

Using thermochemical technologies – which heat waste materials such as polyester to 600-800oC, turning them into a gas which combines with hydrogen to create new the building blocks of new materials – the researchers believe they’ve established a method which could eliminate the need for new, fossil-derived raw materials.

“There are enough carbon atoms in waste to meet the needs of all global plastic production. Using these atoms, we can decouple new plastic products from the supply of virgin fossil raw materials. If the process is powered by renewable energy, we also get plastic products with more than 95 per cent lower climate impact,” said Henrik Thunman, a university professor of energy technology.