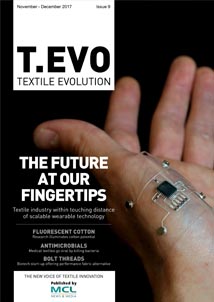

NORTH CAROLINA – A collaborative effort comprising researchers in textiles, electricals, computing and biomedical engineering at NC State University has yielded a lattice made from conductive yarns that the team believes offers a more comfortable, lightweight solution for measuring pressure points in the sockets of prosthetic limbs.

The research team, whose work has since been published in the IEEE Sensors Journal, has developed the system over a number of years to provide an alternative to the often bulky, hard and heavy rigid sensors currently used in this capacity.

“These are not things that amputees can use on a daily basis because rigid sensors negatively affect the fit of amputees' prosthetics,” said the study’s first author, graduate student Jordan Tabor. “Rigid sensors can also cause discomfort. We designed sensors that can be integrated into textiles in a way that doesn't cause any additional discomfort for the user, and could be worn on a more regular basis."